Materiały drewniane i odpowiadające im techniki obróbki

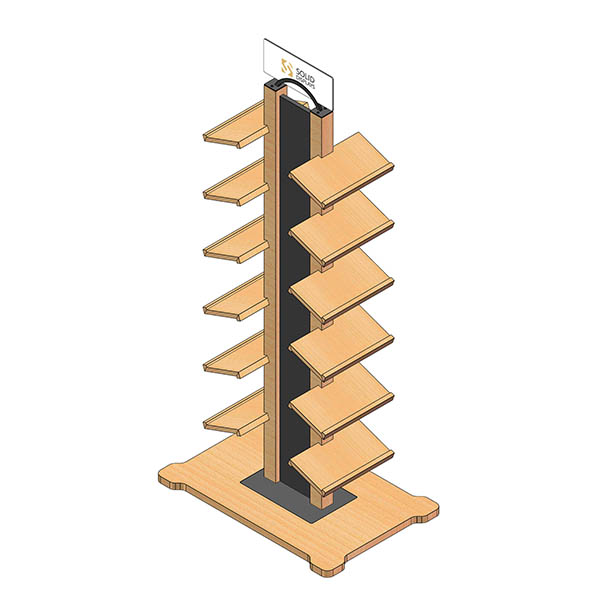

Display stands serve as essential fixtures in various settings, from retail stores to exhibitions, showcasing products and merchandise with efficiency and style. Behind their functionality and aesthetics lie an array of materials carefully chosen for their unique properties and suitability. Among the diverse options available, six materials stand out as staples in display rack construction: Medium Density Fiberboard (MDF), Particle Board (PB), Plywood, Oriented Strand Board (OSB), Solid Woodoraz Bamboo Plate. Each material brings its characteristics and advantages to the table, catering to different needs and preferences in design and functionality. Let's delve into the features and applications of these common wood materials, shedding light on their roles in shaping the landscape of display rack craftsmanship.

MDF (Medium Density Fiberboard)

MDF is made from wood fibers or other plant fibers that are broken down, separated, and dried before being pressed with urea-formaldehyde resin or other synthetic resins under heat and pressure. The resulting board has a density range of 0.50 to 0.88 g/cm³. Additives may be included to enhance the board's properties.

MDF has excellent physical and mechanical properties and good workability, making it suitable for various thicknesses. It's widely used in the furniture manufacturing, construction, and interior decoration industries, replacing natural wood in applications such as flooring, wall panels, and partitions. MDF is cost-effective, easy to process, and more economical than natural wood. It utilizes limited wood resources efficiently, supporting sustainable forestry development.

Key Characteristics and Performance:

- Uniform Internal Structure: Moderate density and stable dimensions with minimal deformation.

- Superior Physical and Mechanical Properties: Better bending strength, internal bond strength, modulus of elasticity, and screw holding capacity compared to particle board.

- Smooth Surface: Facilitates secondary processing like veneering, painting, and printing.

- Large Sheet Size and Thickness Variation: Available in thicknesses from 2.5 to 35 mm, suitable for various applications.

- Good Machinability: Similar or even superior to wood in sawing, drilling, mortising, milling, and sanding.

- Easy to Carve and Shape: Ideal for creating detailed furniture parts and can be painted directly without edge banding.

- Special Additives: Can include waterproof, fireproof, and anti-corrosion agents for specialized uses.

Main Types:

- Interior MDF (MDF): Not resistant to water or high humidity. Natural color.

- Moisture-Resistant Interior MDF (MDF.H): Short-term resistance to cold water and humidity. Green color.

- Exterior MDF (MDF.E): Resistant to weathering, water immersion, and humid conditions. Gray color.

Zastosowania:

Used in display cabinets, showcases, wooden containers, wood frames, floor displays, shelves, logos, top boards, display stands, display racks, countertop displays, and combined with other materials for complete products or projects.

MDF Processing:

- With Decorative Laminate:

- Laminate or veneer MDF as per color and design.

- Cut using CNC, drill holes, edge band, and chamfer for packaging.

- If veneered, typically varnished or stained.

- Lacquer Painting:

- Cut and shape using CNC.

- Assemble parts.

- Apply putty.

- Sand the surface.

- Apply paint as specified.

Key Points:

- Common Density: 0.75 g/cm³ (L/M * W/M * T/MM)

- Material Grades: E1, E2 (Europe) and P1, P2 (USA), referring to formaldehyde content. The default is E1 grade.

- Laminating: Applying a decorative surface to MDF, can be single or double-sided.

- Melamine: The most popular material, a type of paper impregnated with melamine resin.

- Edge Banding: Sealing the edges of melamine boards for aesthetics and moisture resistance.

- Veneering: Applying wood veneer to MDF for a solid wood appearance, usually with edge banding.

- Lacquer Painting: Spraying specified colors and finishes on MDF.

PB Board (Particle Board, Chipboard)

Particle board, also known as chipboard, is made by cutting various branches, small-diameter wood, fast-growing timber, wood shavings, and other wood fragments into specific sizes. These fragments are then dried and mixed with adhesives, hardeners, waterproofing agents, and other chemicals, and pressed under certain temperature and pressure conditions to form a type of engineered wood. The particles in particle board are arranged unevenly. Although sometimes referred to as particle board, it should not be confused with solid wood particle board, which has similar manufacturing processes but is of significantly higher quality.

Classification:

- By Use:

- Class A particle board

- Class B particle board

- By Structure:

- Single-layer particle board

- Three-layer particle board

- Graded structure particle board

- Oriented particle board

- Waffle particle board

- Molded particle board

- By Manufacturing Method:

- Flat-pressed particle board

- Extruded particle board

- By Raw Materials:

- Wood particle board

- Bagasse particle board

- Flax shive particle board

- Cotton stalk particle board

- Bamboo particle board

- Cement particle board

- Gypsum particle board

- By Surface Condition:

- Unfinished Particle Board:

- Sanded particle board

- Unsanded particle board

- Finished Particle Board:

- Melamine-faced particle board

- Decorative laminate-faced particle board

- Veneer-faced particle board

- Surface-coated particle board

- PVC-faced particle board

- Unfinished Particle Board:

Production Processes:

Particle board production methods vary based on the forming and hot-pressing equipment used. They include batch production using flat-pressing methods and continuous production using extrusion or roller-pressing methods. Flat-pressing is the most commonly used method in practical production.

Advantages and Disadvantages:

- Advantages:

-

- Good Sound Absorption and Insulation: The particle board provides excellent thermal insulation and sound absorption properties.

- Uniform Structure: The cross-aligned structure of the particles results in similar properties in all directions, though it has relatively lower lateral load-bearing capacity.

- Smooth Surface: Suitable for various laminates and finishes.

- Environmental Considerations: It uses relatively less adhesive during production, making it relatively eco-friendly.

- Disadvantages:

-

- Particle Structure: The internal particle structure makes it difficult to shape and mill.

- Cutting Issues: The board is prone to chipping during cutting, requiring higher quality machinery and tools. It is not suitable for on-site fabrication.

Key Relevant Information:

- Export Density: The commonly used density is 0.7 g/cm³ (L/M * W/M * T/MM).

- Material Grades: E1, E2 (Europe) and P1, P2 (USA), indicating formaldehyde content. The default is E1 grade.

- Laminating: This involves pressing a decorative surface onto the MDF, which can be single or double-sided.

- Melamine: The most popular material for laminating, melamine paper is used extensively.

- Edge Banding: Sealing the edges of melamine boards to enhance appearance and moisture resistance.

Industry Applications:

Particle board is widely used for various display cabinets, shelves, and other components in the exhibition industry.

Plywood

Plywood is a type of engineered wood made from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. This cross-graining technique reduces the wood's tendency to split when nailed at the edges, reduces expansion and shrinkage, and improves strength consistency.

Plywood is one of the most commonly used materials in furniture making and is one of the three major types of engineered wood products. The veneers are typically arranged in odd numbers, such as three, five, or seven pieces, to maintain balance and stability. Common types of plywood include three-ply and five-ply. Plywood improves the utilization rate of wood and is a primary method of conserving wood resources.

Typical Specifications:

- Wymiary: Common sizes are 1220×2440 mm.

- Thickness: Typical thicknesses include 3 mm, 5 mm, 9 mm, 12 mm, 15 mm, and 18 mm.

- Wood Species: Common species used include beech, camphor, willow, poplar, eucalyptus.

Structural Principles:

To minimize the anisotropic properties of natural wood and ensure uniformity and stability, plywood follows two main structural principles:

- Symmetry: The veneers on both sides of the central ply should be symmetrical in terms of wood species, veneer thickness, number of layers, grain direction, and moisture content.

- Perpendicular Layers: Adjacent veneer layers should have grains oriented perpendicular to each other.

These principles ensure that the structure of the plywood is balanced and stable, which is why plywood usually has an odd number of layers. The layers in plywood are named as follows:

- Face Veneer: The outermost veneer on the front.

- Back Veneer: The outermost veneer on the back.

- Core Veneer: The inner veneers, with those parallel to the face veneer grain called "long core" or "center core."

Key Related Information:

- Laminate: This refers to the process of applying a decorative surface to MDF, commonly known as pressing or veneering. This can be done on one or both sides.

- Melamine: The most popular material used in laminates, melamine paper provides a durable and attractive finish.

- Edge Banding: The process of sealing the edges of melamine boards to enhance appearance and moisture resistance.

- Veneer: Applying a wood veneer to MDF gives it the appearance of solid wood, often with matching wood veneer edge banding.

- Lacquer Painting: Spraying MDF with a specified color and finish.

Zastosowania:

Plywood is used in high-end shelving, display cabinets, and other applications where a finish similar to solid wood is desired. It's often veneered with solid wood veneer to achieve a high-quality, durable finish that mimics the look of solid wood.

OSB (Oriented Strand Board)

Oriented Strand Board (OSB) is primarily made from small-diameter softwood and hardwood trees such as eucalyptus, pine, and poplar. These materials are abundant and can be sourced widely, allowing for the production of large panels (e.g., 8×32 feet or 12×24 feet). The manufacturing process involves creating wood strands of specific geometrical shapes (typically 50-80 mm long, 5-20 mm wide, and 0.45-0.6 mm thick). These strands are dried, coated with adhesive, oriented, and then hot-pressed to form the board.

OSB has seen significant growth in its use within the furniture industry, with many large furniture manufacturers adopting it due to its low formaldehyde emissions, durability, and lighter weight compared to MDF (Medium Density Fiberboard) and particle board (also known as chipboard or melamine board).

OSB is one of the fastest-growing engineered wood products globally, widely used in construction, decoration, furniture, and packaging in developed regions like North America, Europe, and Japan. It is considered an upgrade from plywood and blockboard.

Advantages and Disadvantages:

Advantages:

- Environmental Standards: OSB uses high-grade environmental adhesives that comply with Europe's highest environmental standards (EN300). The finished product meets the European E1 standard for formaldehyde emissions, which are almost zero, making it comparable to natural wood and far superior to other types of engineered wood. It is considered one of the highest-grade decorative panels on the market, meeting demands for environmental protection and healthy living.

- Cost-Effectiveness: OSB is priced similarly to high-end blockboard but offers superior environmental and physical properties, making it a highly competitive material.

Disadvantages:

- Surface Smoothness: OSB is less smooth compared to other types of engineered wood. The surface can be rough and splintery if not properly finished with varnish or other coatings, making it less pleasant to touch.

Industry Applications:

OSB is widely used in making large items such as various display cabinets, back panels, decorative panels, and shelves.

- Lacquer Painting: Typically, OSB is sanded smooth to remove splinters and then coated with varnish to enhance its appearance and touch.

- Natural Effect: OSB has a natural, rustic appearance, which can be a desirable aesthetic in many applications.

Solid Wood

Solid wood refers to wood boards made from complete pieces of wood (lumber). These boards are typically classified by the type of wood used, such as pine, beech, oak (red and white oak), and various other hardwoods. Unlike engineered wood products like plywood, particle board, and OSB, which are made from wood fragments and adhesives, solid wood is prized for its natural beauty, durability, and the unique characteristics of the wood species from which it is made.

Advantages and Disadvantages:

Advantages:

- Durability and Strength: Solid wood is strong and long-lasting.

- Natural Aesthetics: It offers natural, unique wood grain patterns and textures.

- Aromatic Properties: Many types of solid wood have a natural, pleasant fragrance.

- Health Benefits: Solid wood has good hygroscopicity and breathability, which can contribute to a healthier indoor environment.

- Environmental Impact: It is a more environmentally friendly option, as it doesn't involve synthetic adhesives and chemicals found in engineered wood products.

Disadvantages:

- Koszt: Solid wood is generally more expensive than engineered wood products.

Common Types of Solid Wood:

- Pine Wood: Affordable and lightweight, often used for furniture and construction.

- Beech Wood: Hard and strong, with a fine, tight grain, suitable for furniture and cabinetry.

- Oak Wood: Known for its strength and durability, available in red and white varieties, commonly used in high-end furniture and flooring.

- Various Hardwoods: Other hardwoods can be used based on availability and desired characteristics.

Key Related Information:

- Lacquer Painting: Applying lacquer paint or varnish to solid wood not only enhances its appearance with a specified color and finish but also protects the wood from damage and wear.

Industry Applications:

Solid wood is used for making high-end furniture, support legs, frames, shelves, and various types of cabinets. It is preferred for its superior quality and aesthetic appeal, despite its higher cost. The price of solid wood products can vary significantly depending on the type of wood used.

Bamboo Plate

Bamboo plates are engineered boards made from meticulously processed bamboo strips that are glued and pressed together. The production of bamboo plates typically involves using large-diameter bamboo (usually 4-6 years old), which undergoes various processes such as sawing, splitting, rough planing, high-temperature steaming, high-pressure carbonization, drying, fine planing, sorting, assembling, pressing, and sanding. This extensive processing results in bamboo plates with excellent physical properties, including low water absorption, minimal swelling, resistance to cracking, and stability.

Characteristics:

- High Strength and Stability: Bamboo plates undergo high-temperature, high-pressure steam carbonization to remove sugars and fats from the bamboo, increasing its strength and stability.

- Anti-Microbial and Insect Resistance: The carbonization process also ensures the elimination of pests and enhances the material's resistance to mold and decay.

- Environmental Friendliness: Bamboo is a renewable resource, and the manufacturing process uses eco-friendly adhesives, ensuring the end product meets European E1 environmental standards for formaldehyde emissions.

- Aesthetic Appeal: Bamboo plates retain the natural grain and beauty of bamboo, offering a fresh, elegant, and comfortable look.

Process:

- Raw Material Preparation: Fresh, high-quality bamboo (4-6 years old) is selected and cut into strips.

- High-Temperature Steaming and Carbonization: The bamboo strips undergo high-temperature steaming and high-pressure carbonization to remove sugars and fats, enhancing strength and stability.

- Drying and Planing: The strips are dried to a constant moisture level and finely planed.

- Assembly and Pressing: The strips are sorted, stacked, and pressed together using environmentally friendly adhesives under high temperature and pressure to form various sizes of boards.

- Sanding and Finishing: The boards are sanded to a smooth finish, ready for use.

Key Related Information:

- Lacquer Painting: Bamboo plates can be lacquered to enhance their appearance and protect the surface, similar to solid wood.

- Environmental Standards: The final product adheres to the European E1 standard, ensuring low formaldehyde emissions and making it safe for use in homes and other indoor environments.

Industry Applications:

Bamboo plates are used for making shelves, small bases, decorative back panels, and can be explored for new applications in various industries. They are an excellent material for creating bamboo crafts and furniture, appealing to consumers who prefer natural, environmentally friendly products. The inherent properties of bamboo make it a versatile and attractive option for both functional and decorative uses.

In essence, the features and applications of these common wood materials shed light on their technical aspects. It underscores their significance in elevating display fixtures' visual appeal and functionality across various settings. As the demand for innovative and sustainable display solutions grows, so does the importance of understanding and harnessing the unique properties of these staple materials. Through thoughtful consideration and creative integration, drewniane wyświetlacze will continue to serve as indispensable fixtures, blending efficiency with style in retail stores, exhibitions, and beyond.

Powiązane posty

Które materiały są najlepsze dla niestandardowych wyświetlaczy POP?

Materiały metalowe i odpowiadające im techniki przetwarzania

Materiały akrylowe i odpowiadające im techniki przetwarzania